Index

Home

About

Blog

From: jobst.brandt@stanfordalumni.org

Subject: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <S3Frb.5619$Wy2.67389@typhoon.sonic.net>

Date: Mon, 10 Nov 2003 05:09:06 GMT

For those who like to make and own something special, I propose that

you build a double acting tire pump, one that will fill a conventional

28mm road tire to 100psi in ten strokes. I built such gadgets for

myself and friends who use them for all tire pumping. Check out Carl

Fogel's web site at:

Expand the drawing to full screen if you have such a capability so you

can read what's on the page. These are to scale but are only the

instruction sheet.

Jobst Brandt

jobst.brandt@stanfordalumni.org

From: jobst.brandt@stanfordalumni.org

Subject: Re: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <pX8sb.5967$Wy2.77481@typhoon.sonic.net>

Date: Tue, 11 Nov 2003 17:24:37 GMT

Mike DeMicco writes:

>> The link on that page "Double action coaxial system." doesn't work

>> when I click on it and the index page does not list that pump. I

>> don't believe their claim of 145psi in ten strokes unless they mean

>> for a 20 x 1 tire. Of course, we see such claims all the time

>> without qualifying the claim.

>> The old Zefal two side-by-side cylinder pump is so crudely made

>> that it doesn't work. Can you give a better URL for their Coaxial

>> Pump?

> Try http://www.zefal.com/anglais/ppiedhpang.html It's the pump

> called 100 HP Doubleshot. I've got ~ 12 yr. old Zefal Doubleshot,

> and it does inflate a tire pretty quickly.

I think I have seen this pump. It delivers its air to the tire on the

up-stroke. I see the hose comes out of the top of the pump and that's

where the gauge is. My coaxial compound pump delivers on the

down-stroke, the powerful one, a major design advance. The design

feature that made that possible is that the piston rod is hollow,

something hand pump designers never discovered. I have seen several

antique pumps since I built mine, that have this problem. One of them

even turned the whole thing upside down, the outer body of the pump

going up and down with each stroke.

Jobst Brandt

jobst.brandt@stanfordalumni.org

From: jobst.brandt@stanfordalumni.org

Subject: Re: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <zwgsb.6096$Wy2.78142@typhoon.sonic.net>

Date: Wed, 12 Nov 2003 02:02:07 GMT

Mike DeMicco writes:

>> I think I have seen this pump. It delivers its air to the tire on

>> the up-stroke. I see the hose comes out of the top of the pump and

>> that's where the gauge is. My coaxial compound pump delivers on

>> the down-stroke, the powerful one, a major design advance. The

>> design feature that made that possible is that the piston rod is

>> hollow, something hand pump designers never discovered. I have

>> seen several antique pumps since I built mine, that have this

>> problem. One of them even turned the whole thing upside down, the

>> outer body of the pump going up and down with each stroke.

> (I just ran this test...) I put my thumb over pump nozzle and it

> puts out air on both the up and the downstroke. When pumping a

> tire, I can see the gage rise on both the up and downstroke. I

> pumped up a flat 700x23 tire to 110 psi in 10 full strokes. They

> must be using the inner piston rod as a pump, as it's ~ 1" O.D.

> Most of the pump is made of plastic. At the top of the stroke it

> makes a pop noise. I don't know what that's all about - I hope it's

> not a leak, but it's always done that. It seems to work real well

> though.

Of course it put out air on both strokes, it's a double acting pump,

but when it is pumping a tire that is over the pre-stage pressure, no

air comes out of the hose until the high pressure stroke. You ought

to be able to tell when air is going into the tire both by how hard

you must push/pull and the sound of the Presta valve opening.

Besides, the pre-stage always requires the same force while the

pressure stroke requires more force as tire pressure increases.

So once more, does it deliver on the up or down-stroke?

Just for curiosity, what are the two tube diameters. Mine are 1.5"

and 7/8" with 0.049 wall, (I also built ones with a 1.75 OD) so you

can see what volume is swept with each cycle. My impression is that

the Zefal pump is smaller volume and therefore probably doesn't pump

as much as they claim.

Jobst Brandt

jobst.brandt@stanfordalumni.org

From: jobst.brandt@stanfordalumni.org

Subject: Re: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <qHwsb.6187$Wy2.80907@typhoon.sonic.net>

Date: Wed, 12 Nov 2003 20:25:58 GMT

Carl Fogel writes:

> I'm still trying to suspend my disbelief.

> This bizarre pump intentionally placed its exposed inner

> rod/plunger/chamber as close as possible to the floor, the ground,

> and all the available dirt?

> It left the lightest parts sitting on the ground and made the

> operator raise and lower as much weight as possible?

> The seals were placed as high as possible to help them dry out?

> I mean, this might make sense for a really bad bilge pump or a

> pogo-stick, but a tire pump? Do you have any idea what their

> reasoning was? Or a link to a picture? Where did the air-hose

> emerge?

The reason for the upside-down design was, as I said, to get the air

of a two stage pump to come out of the bottom, since no one discovered

how to do that with an even number of chambers. As you see, Zefal did

not solve the problem either as Doug Milliken described.

I can send you a picture of my pump and others.

Jobst Brandt

jobst.brandt@stanfordalumni.org

From: jobst.brandt@stanfordalumni.org

Subject: Re: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <1mBsb.6231$Wy2.81386@typhoon.sonic.net>

Date: Thu, 13 Nov 2003 01:44:29 GMT

> For those who like to make and own something special, I propose that

> you build a double acting tire pump, one that will fill a conventional

> 28mm road tire to 100psi in ten strokes. I built such gadgets for

> myself and friends who use them for all tire pumping. Check out Carl

> Fogel's web site at:

> Expand the drawing to full screen if you have such a capability so you

> can read what's on the page. These are to scale but are only the

> instruction sheet.

Photos at:

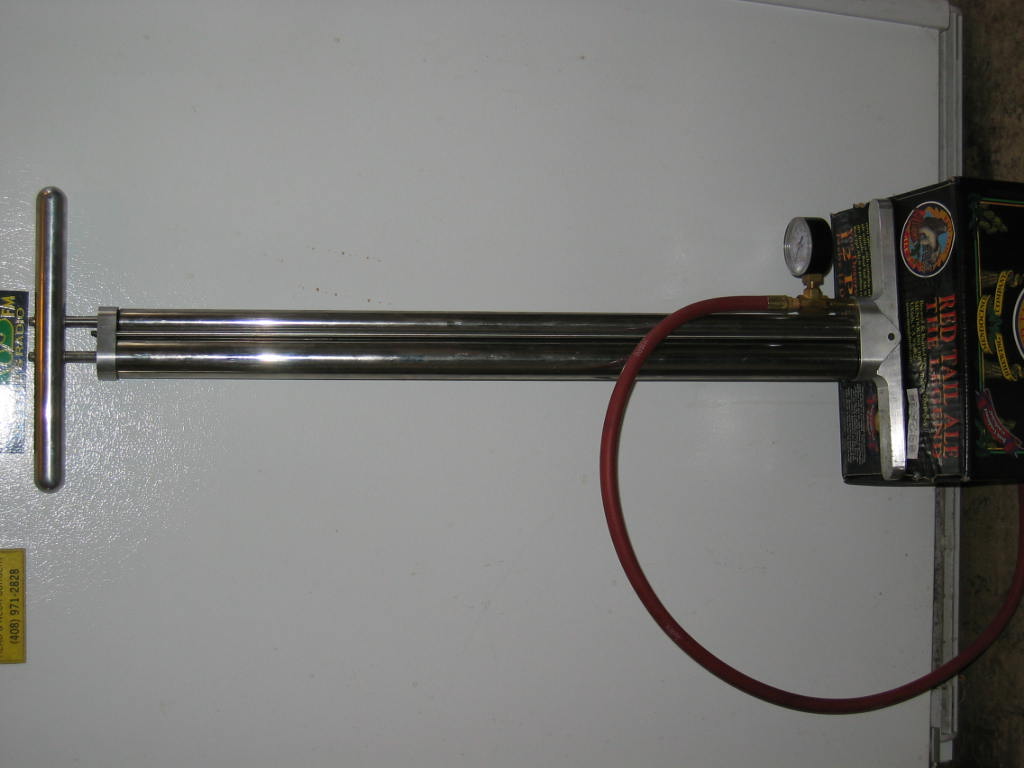

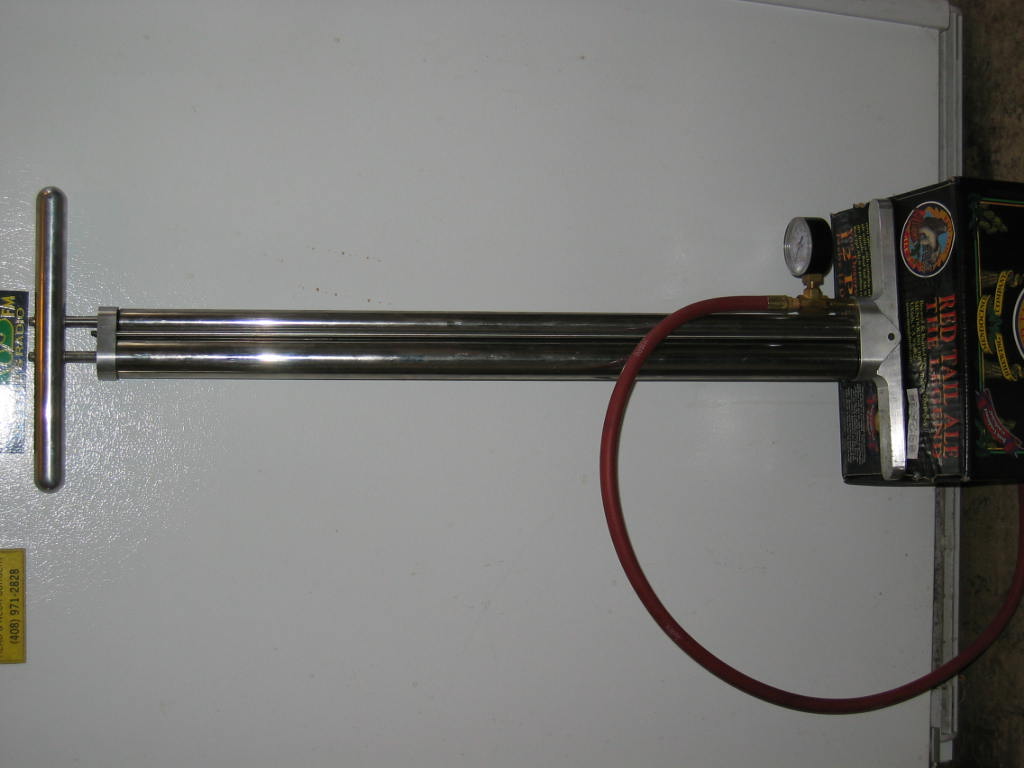

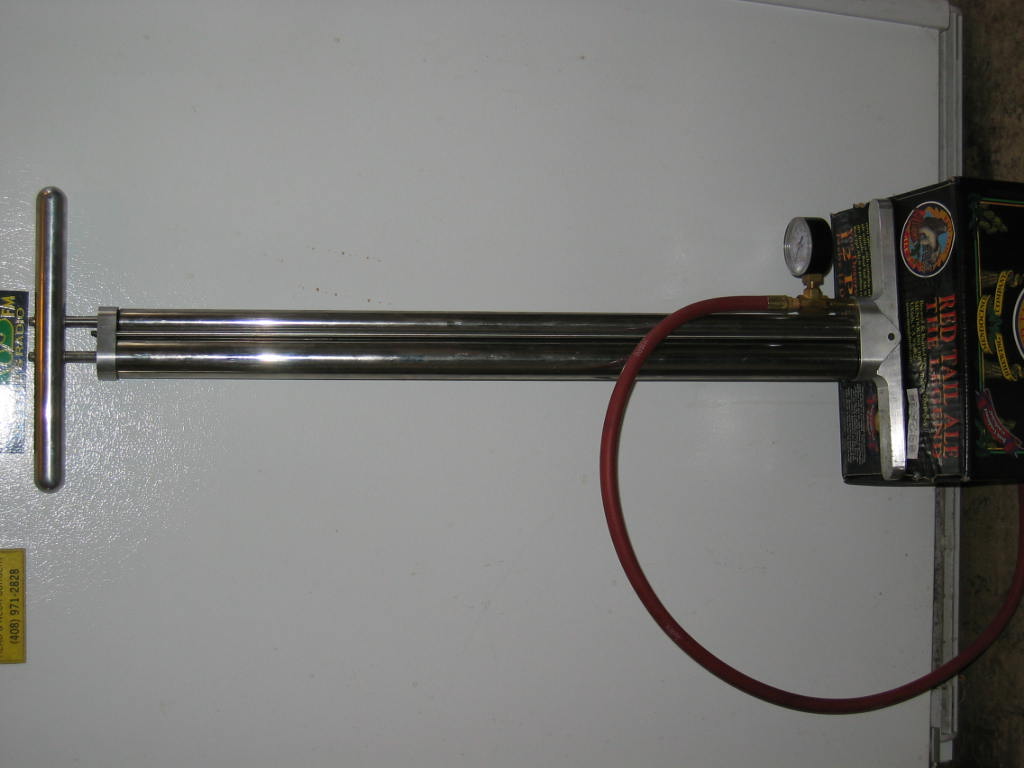

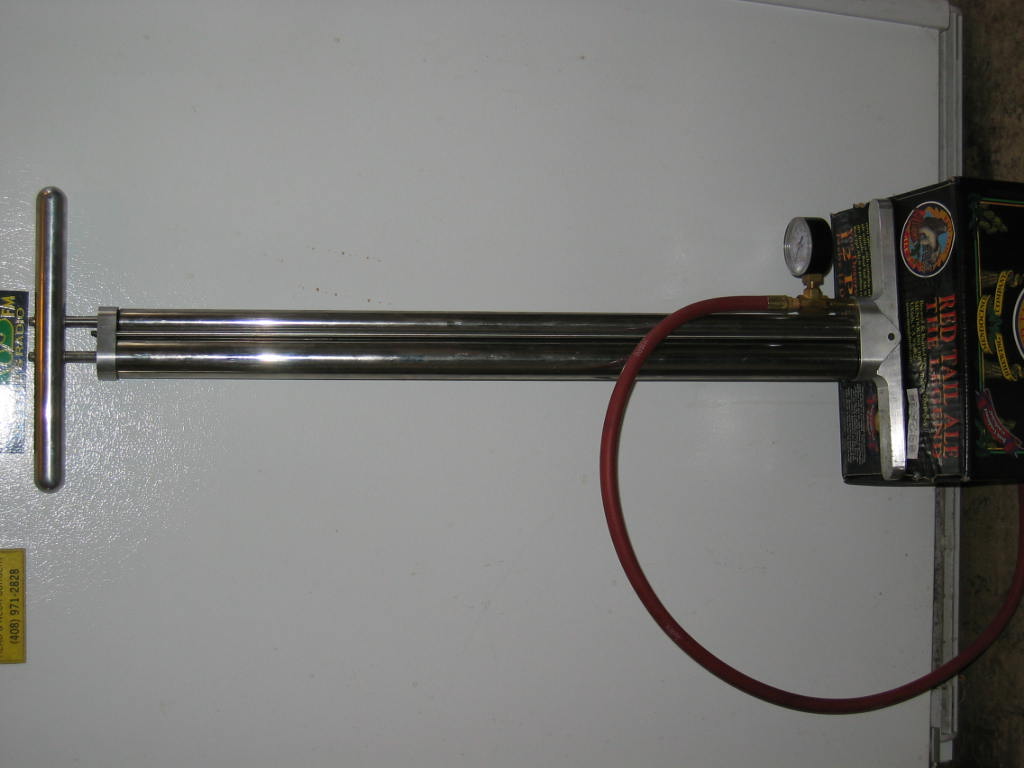

(Brandt design)

(Three pumps)

(Brandt design)

004 is the concentric pump.

005 is of the Zefal Double Shot, A 3-chamber pump, and the upside down

2-chamber pump that has its hose barb on the foot bar.

006 is my first design of a side-by-side double acting pump.

Drawings are available in DXF or DWG format. Unfortunately my translator

converts each cross hatching of an area to a 'part' that is made of lines.

Jobst Brandt

jobst.brandt@stanfordalumni.org

From: jobst.brandt@stanfordalumni.org

Subject: Re: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <Ko1tb.6395$Wy2.89679@typhoon.sonic.net>

Date: Fri, 14 Nov 2003 09:38:50 GMT

Carl Fogel writes:

>> free DFX viewer:

>> <http://adeskftp.autodesk.com/webpub/VoloView/english/vve201setup.exe>

>> (if the link bombs, go to 'autodesk.com' and look for 'VoloView'.)

> Lest anyone be disappointed, the link worked for me just now, but

> it's a 23.4 mb file and took over 7 minutes on a fair cable

> connection. A phone connection might take hours and crash.

I found it has a crude interface and doesn't recognize DXF files with

a lower case file extension ".dxf". The real thing costs $100 for the

VoloView in contrast to the free VoloView Express version. I'm not

thrilled. I'm looking at an appendage for my CAD program called

ME2Ras (ME10 to Raster). It costs a bit more but claims convert ME10

to a dozen file types that people like to use.

Jobst Brandt

jobst.brandt@stanfordalumni.org

From: jobst.brandt@stanfordalumni.org

Subject: Re: Double acting tire pump

Newsgroups: rec.bicycles.tech

Message-ID: <sMFsb.6257$Wy2.83218@typhoon.sonic.net>

Date: Thu, 13 Nov 2003 06:45:44 GMT

Tim McNamara <timmcn@bitstream.net> writes:

>> For those who like to make and own something special, I propose

>> that you build a double acting tire pump, one that will fill a

>> conventional 28mm road tire to 100psi in ten strokes. I built such

>> gadgets for myself and friends who use them for all tire pumping.

>> Check out Carl Fogel's web site at:

>> Expand the drawing to full screen if you have such a capability so

>> you can read what's on the page. These are to scale but are only

>> the instruction sheet.

> Interesting. Where to source parts, though?

You make the parts in a machine shop and purchase the material and

O-rings from conventional vendors.

Photos at:

(Brandt design)

(Three pumps)

(Brandt design)

>> 004 is the concentric pump.

>> 005 is of the Zefal Double Shot, A 3-chamber pump, and the upside

>> down 2-chamber pump that has its hose barb on the foot bar.

>> 006 is my first design of a side-by-side double acting pump.

>> Drawings are available in DXF or DWG format. Unfortunately my

>> translator converts each cross hatching of an area to a 'part' that

>> is made of lines.

> No doubt anyone with an engineering background would already know

> the answer to this question, but I don't. Why is one barrel smaller

> than the other?

If it weren't then there would be not much compression ratio between

the two cylinders, or if they were both large, you couldn't push the

delivery piston down. The small cylinder is about the size of a Silca

Impero frame fit pump, the larger one is chosen to charge up the

smaller one on the up-stroke with up to 15lbs force depending on how

large a big tube is chosen.

> Are the drawings different than the GIFs?

Drawings are to scale, have dimensions and can be measured. They are

essentially full sized unless scaled for output. There are other

drawings like RR locomotives (full size). The fine detail is only

visible in a CAD system. See:

http://steamcad.railfan.net/bigboy.htm

http://steamcad.railfan.net/shay.htm

http://steamcad.railfan.net/

This last URL has the sounds of most kinds of locomotives and bad

track, including SP4449, Shay, SP2470, and diesels.

Like elliptical oil drops, the syncopated beat of a steam engine is

also not understood by railroaders and the effect it has on engines

pulling heavy loads.

Jobst Brandt

jobst.brandt@stanfordalumni.org

Index

Home

About

Blog