Index

Home

About

Blog

From: John De Armond

Newsgroups: rec.outdoors.rv-travel

Subject: Re: Help with atwood water heater (A thermocouple by any other name.)

Date: Sat, 06 May 2006 00:19:21 -0400

Message-ID: <j88o5250keuo1m1mstudqcpp6h73jitenl@4ax.com>

On Fri, 5 May 2006 09:03:42 -0400, "Steve Wolf" <news@w8iz.com> wrote:

>OK, I'll bite.

>

>What is the difference between a thermocouple and a flame rod? They appear

>to be doing the same job but in what way do they do it differently?

>

>Yeah, I can see it. "Honey? I have to go to the store to fix my flame

>rod."

A thermocouple is a junction of two dissimilar metals that generates a

small potential (at high current in this case.) In the gas valve, it

powers a solenoid that holds the safety valve open. When the

thermocouple cools enough, the solenoid releases and the valve closes.

On the other side, the valve has to be held in long enough for the

thermocouple to get hot. A thermocouple system is self-contained and

requires no outside source of power.

A variation of this is the "thermopile", a series of junctions in

series that when heated, produce enough voltage to operate external

devices. The normal standard pile generates 750mv. This is enough to

send current through an external thermostat and operate a gas valve.

Thermopiles are commonly seen on restaurant deep fryers and some

self-contained furnaces.

A flame rod is a simple piece of heat-resistant metal (nichrome,

inconel, etc) in contact with a flame. A flame consists of ionized

particles undergoing chemical reactions and therefore is conductive.

The flame rod takes advantage of that fact. The rod has a small

potential on it and when the flame touches it, a small current flows

from the rod through the flame to ground. This current is detected

and uses to "prove" the flame. A flame acts as a diode but I don't

recall the direction of electron flow and that effect isn't used in

this application.

The rod's response is instantaneous. That, and there being nothing to

degrade, are the two main benefits. The major detraction is that

active, powered electronics are needed to process the signal.

All pilotless gas systems use flame rods. If the ignition system is

by spark then the flame rod and the ignition rod may be the same.

Other systems use separate spark and flame rods. Yet other ignition

systems such as the hot body ignitor don't involve the use of sparks

at all.

A similar application is the pilot light sustainer. This little

gadget detects when the pilot light goes out and sparks to relight it.

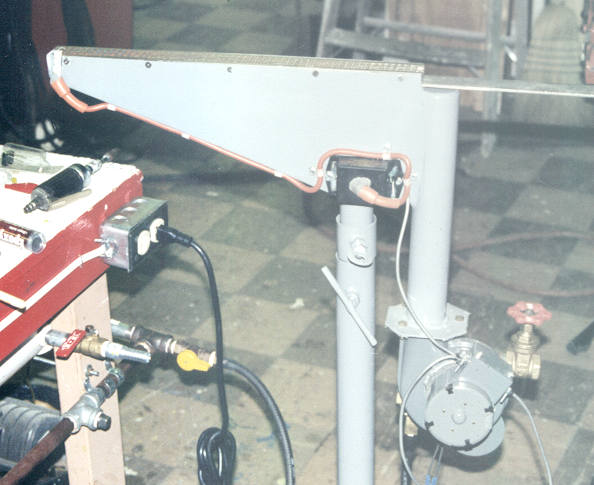

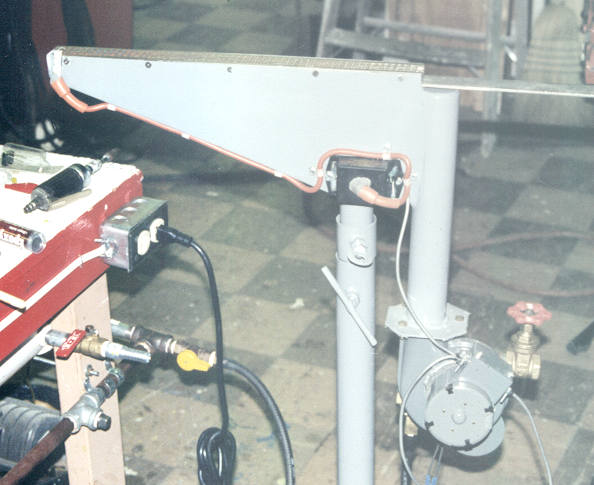

Here is a photo of one on the side of my neon plant's ribbon burner.

In this case, I'm using it as the main ignitor.

John

From: John De Armond

Newsgroups: rec.outdoors.rv-travel

Subject: Re: Help with atwood water heater

Date: Fri, 05 May 2006 03:17:02 -0400

Message-ID: <pkul52l2vc13jk6tk475jvpvigpd2s656n@4ax.com>

On Thu, 04 May 2006 15:06:21 -0400, Frank Tabor <ftabor@gmail.com>

wrote:

>>There appears to be magnetism on the solenoid. The igniter keeps

>>sparking even when it's lit and then shuts down. Would it be a good

>>guess on a faulty circuit board then?

>>

>

>Control board or the thermocouple. It doesn't know it's lit.

Since it doesn't have a thermocouple, that can't be it.

After you verify that the valve(s) are fully opening and the pressure

is correct, gain access to the burner and inspect the flame rod. The

flame must actually touch this rod to form the flame proving signal. A

partially open solenoid can result in a flame too small to touch the

rod. Corrosion or distortion in the sheet metal can also result in

insufficient flame contact. Bend the rod over a little if necessary

(heat it red hot with a torch before bending or it'll break) to make

better flame contact.

Only after you do all this, suspect the board. The flame signal is

very small so the first thing to do is look for leakage paths -

charred insulation on the flame sensing wiring, crud buildup on the

board - especially if you've been near saltwater - and stuff like

that. Only after all that, start thinking about a bad board.

I've seen exactly one bad flame sensing circuit in my working on these

systems. That was on a board that was 30+ years old and the caps had

dried out. I changed out a couple of caps (actually had a student

change 'em) and the board worked fine.

John

Index

Home

About

Blog